Introducing

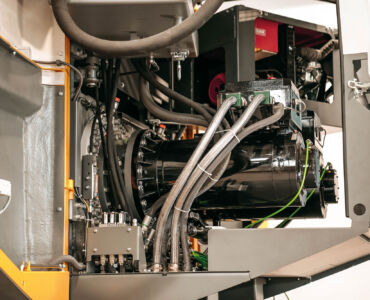

A high volume, dual shaft machine, with an aggressive and modular cutting table, the ZR has been specifically engineered to tackle difficult materials, ranging from metals and large domestic appliances, to construction waste, wood, and more.

With a low speed, high torque drive, it can process severe duty applications with ease, for multi-shift, continuous operation, and a high level of plant availability. This impressive uptime – plus power consumption costs up to 75% less than competitor machines – means the ZR promises the lowest life cycle costs in its class. In fact, with versatility and easy maintenance at its core, it practically pays for itself.

A high quality homogenous output is guaranteed too, which makes this the perfect shredder for volume reduction, recycling, alternative fuel production, and more.

Key Highlights

Quick design feature overview

Two models available – the ZR2400H, for the high throughput, rough shredding of bulky waste, C&I waste, waste wood, MSW, mattresses, carpets, railway sleepers, bales and rolled goods; and the ZR2400W perfect for metals, e-scrap and large domestic appliances.

Bi-directional shaft rotation means the cutters grab, shear and liberate material in forward and reverse, for continuous operation.

Large in-feed space, great when handling even the bulkiest of materials.

Low speed, high torque for high resistance against non-shreddable items.

Ideal for volume reduction (90% <300mm), material breakdown for further treatment, and alternative fuel production.

Efficient electric drive with water-cooled synchronous motors for 75% less energy consumption than standard diesel hydraulic drive.

Available as a static or mobile machine.

Supplied with intelligent condition monitoring tool, UNTHA GENIUS.

INPUT MATERIALS

-

1

Metals

-

2

E-scrap

-

3

Bulky waste

-

4

Construction & Demolition (C&D) waste

-

5

Commercial & Industrial (C&I) waste

-

6

Waste wood

-

7

Municipal Solid Waste (MSW)

-

8

Mattresses

-

9

Carpets

-

10

Baled and rolled goods

Specification

UNTHA ZR Shredder

- Drive Power (kW)

- Rotor diameter (mm)

- Speed (rpm)

- Number of cutters

- Feed opening (mm)

- Screen diameter (mm)

- Weight (kg)

- Noise levels

- 2 x 132 kW

- 900

- Up to 55

- 16

- 4360 mm

- No screen, just cutting table. -> 90% < 300 mm

- 19.000 kg (stationary) 39.000 kg (mobil-e)

- Same as XR